Medical

The use of UV curing systems and adhesives is an important assembly technique for medical device manufacturing due to their rapid processing, cure on-demand nature, ease of automation, low temperature, and lower energy requirements. OmniCure® UV curing systems are ideal for assembling various plastics, glass, stainless steel, rubber and joining similar or dissimilar substrates as part of a controlled UV assembly process.

Excelitas offers a selection of OmniCure UV curing systems for medical device assembly, including UV spot and UV LED area curing systems for a complete solution to any of your UV assembly processes. Features such as Closed-Loop Feedback, precise irradiance control and wavelength selection provide medical device manufacturers with a controlled and repeatable UV assembly process to improve product yields and reliability. By maintaining strict process control of critical parameters such as delivered optical energy, product temperature, spectral content and ensuring optimal optical maintenance, medical device manufacturers will benefit from improved repeatability of their UV curing process. Our UV curing systems are well suited for high volume, automated processes, or manual assembly, designed to reduce scrap material costs and lower operating costs.

Ideal Medical Device Manufacturing Applications include:

| Catheters | Anesthesia Masks | IV Delivery Systems |

| Cannulas | Angioplasty Accessories | Medical Coatings |

| Endoscopes | Arterial Locators | Medical Filters |

| Hearing Aids | Atraumatic Guideware Tips | Rubber Silicones |

| Hydrogels | Blood Oxygenators | Respiratory Masks |

| Needles | Chest Drainage Devices | Sensing Devices |

| Tubing and Connectors | Syringes | Tubing Drainage Sets |

Catheters

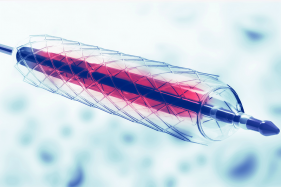

UV spot curing is used extensively in manufacturing cardiovascular catheters since there are several bonding applications, such as balloon bonding, hub bonding, and marker bonding, each requiring a strong and repeatable bond of different materials. The market for cardiovascular catheters is forecast to continue its strong growth due to the extent of heart and cardiovascular disease, which is the number one cause of death globally.

UV spot curing is used extensively in manufacturing cardiovascular catheters since there are several bonding applications, such as balloon bonding, hub bonding, and marker bonding, each requiring a strong and repeatable bond of different materials. The market for cardiovascular catheters is forecast to continue its strong growth due to the extent of heart and cardiovascular disease, which is the number one cause of death globally.

Blood Oxygenator Manufacturing and Assembly

Blood oxygenator manufacturing and assembly requires UV adhesives to be cured evenly without inducing stress cracking in the polycarbonate material. Excelitas Technologies’ OmniCure® technology offers unique benefits over and above standard UV curing, ensuring controlled, even, and repeatable curing of the oxygenator for optimal assembly of specialized disposable medical devices. The OmniCure S2000 is the leading UV spot curing system for medical device assembly where lives depend on a repeatable curing process.

Needle Assembly/Hub Bonding

The global syringe market includes a wide variety of syringes type addressing a multitude of market segments utilizing refillable, prefilled, safety and single use syringes. Cannula to hub bonding is a high automated assembly process which requires control, repeatability and low temperature curing from the UV curing from the UV curing system. The hub material can be comprised of various plastic and glass materials while the cannula is invariably stainless steel, making both the selection of the adhesive and appropriate UV curing system critical to a successful UV assembly process.

OmniCure® has multiple UV curing system options for needle assembly including UV spot curing systems for tacking the needle in place and UV LED area curing systems for a complete cure of the adhesive. Features such as Closed-Loop Feedback, precise irradiance control and wavelength selection provide manufacturers of syringes with improved product yields, lower scrap material costs and lower operating costs. By maintaining strict process control of critical parameters such as delivered optical energy, product temperature, and ensuring optimal optical maintenance, medical device manufacturers will benefit from a controlled and repeatable UV assembly process.